Brand: kaitai

Model: G10/ SG2.5, G12/ SG2

Min. Order: 1ton

metal abrasivesteel gritSteel grit production standards:

We strictly according to GB "GB/T18838.3-2008 high carbon steel shot and sand", American steel casting association "SFSA20-66 cast steel abrasive standard", American motorcar engineer association "SAE standards," J827 cast steel shot in Chinese

Black people republic of metallurgical industry "YB/T5149-93 cast steel shot", the U.S. army standard "MIL - S - 851 cleaning and strengthen with metal kind steel grit and steel shot standards" and "international organization for standardization ISO11124-3 standard high carbon steel shot cast

Steel grit standard "to produce

The specification of cast steel grit:

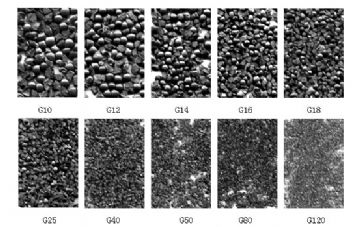

G10/ SG2.5, G12/ SG2.0, G14/ SG1.7 , G16/ SG1.4 ,G18/ SG1.2, G25/SG1.0, G40/SG0.7, G50/SG0.4, G80/SG0.3 , G120/SG0.2

Steel grit, with its main technical indices:

Product Cast Steel Grit

Chemical composition (C) 0.70~1.20%

0.35~1.20%

≥0.4%

≤0.05%

≤0.05%

(Mn)

(Si)

(S)

(P)

Average hardness

(500g load were determined under) GP steel grit:42~52HRC (399~509HV)

GL steel grit:53~60HRC (620~713HV)

GH steel grit :60~64HRC (795~889HV)

Hardness deviation Maximum deviation range ±3.0HRC or ±40HV

Microstructure Tempered Martensite or Sorbite

Density 7.6g/cm3

Steel grit of application:

Cleaning: peen-forming cleaning, body.they, die casting cleaning, casting peen-forming cleaning, forgings peen-forming cleaning, forgings body.they castings rust-removing steel cleaning, steel plate cleaning, cleaning, h-beam cleaning, steel structure cleaning. Derusting: peen-forming derusting, shot peening derusting, casting, forging, steel derusting rust rust, forgings except oxide skin, steel derusting, h-beam derusting, steel structure rust.

Conslidation: shot peening strengthening, heat-treated pieces shot peening, gear shot peening.

Shot peening: steel shot peening, sections of sandblasting, presented.the peen-forming, steel plates, steel shot peening shot peening.

Peen-forming: plate peen-forming, steel shot bla, sections peen-forming.

Play sand: play sand treatment.

Steel shot pretreatment: before painting processing, coating pretreatment, surface pretreatment, presented.the pretreatment, steel pretreatment, steel pretreatment, steel pretreatment, steel structure pretreatment.

Various hardness steel grit:

GP steel grit: new made, be pointed leng shape, in use process edges was soon ground round, especially suitable for the descaling and surface preparationg applications.

GL steel grit: although this type of hardness of the steel grit than GP steel grit, some high during shotblasting also loses its sharp edges, particularly suited to descaling and surface preparationg applications.

GH steel grit: such a high rigidity, in steel grit sandblasting assignments will always maintain edges and corners, to the formation of these rules, the surface of the wool is especially effective. GH steel grit shot peening machine for homework, should consider the construction requirements prior to price factor occasions (e.g. abrasion rolling processing). This steel grits are mainly used for compressed air shot peening equipment.