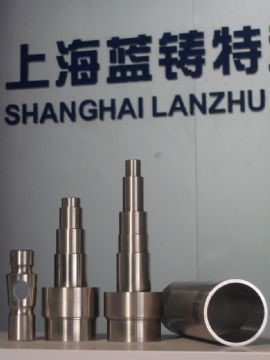

Brand: LANZHU

Model: 板材、带材、管材、锻件协商供应

Min. Order: 1

Corrosion-resistantThe INCOLOY® 800 series of alloys, invented by the

Special Metals Corporation Group of Companies, is the

result of years of monitoring and maintaining the

ultimate chemical properties for high-temperature

strength and resistance to oxidation, carburization and

other types of high-temperature corrosion.

Each one a refinement of the one before, these

alloys have set the industry standard in hightemperature

applications requiring optimum creep and

rupture properties.

INCOLOY nickel-iron-chromium alloy 800 was

introduced to the market in the 1950s to fill the need for

a heat- and corrosion-resistant alloy with a relatively

low nickel content since nickel was, at the time,

designated a “strategic” metal. Over the past forty years

it has been widely used for its strength at high

temperatures and its ability to resist oxidation,

carburization, and other types of high-temperature

corrosion. Applications include furnace components

and equipment, petrochemical furnace cracker tubes,

pigtails and headers, and sheathing for electrical heating

elements.

In 1963, the alloy was approved by the ASME

Boiler and Pressure Vessel Committee, and the design

stresses were published in Code Case 1325. For the first

time, aluminum and titanium were listed as purposeful

additions (at 0.15 to 0.60% each), and annealed material

was differentiated from solution-annealed material. The

new terms “Grade 1, annealed at approximately 1800°F

(980°C)” and “Grade 2, annealed at approximately

2100°F (1150°C)” came into use. The Code Case

covered Sections I and VIII, and listed design stresses

for Grade 1 to 1100°F (593°C) and for Grade 2 to

1500°F (816°C).